Subscribe

Information on new and updated products, upcoming events, and more!

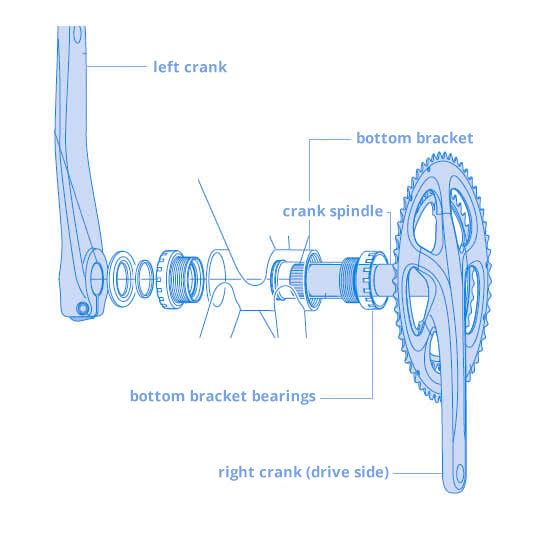

The Bottom Bracket Assembly

Is the foundation of the frame from which all geometry is referenced.

Is the mounting point for the crankset (chainset) to the bicycle and allows the crankset to rotate freely.

Must be able to carry the load from the riders pedaling efforts.

Must be located so that its axis is parallel to the hub axles, and perpendicular to the vertical and longitudinal centerlines of the frame.

Is available in a variety of diameters, widths, and methods to mount the crank bearings.

Components of the Assembly

A spindle to which the crankset attaches.

The bearings that allow the spindle and cranks to rotate.

The chain rings and pedals that attach to the cranks.

The above components fit into the bottom bracket shell which connects to the seat tube, down tube, and chain stays.

Compatibility

Most bottom brackets are designed to work with specific types of frames.

Check the instructions from the manufacturer to determine whether they will work with the type of bike you have.

Price

Choose a price point and then make your selection based on:

The quality of the materials used.

The reputation of the manufacturer.

The customer service they provide.

Reviews

Avoid buying without checking reviews on various sites to see what customers are saying about it.

Brand

Only consider purchasing from a reputable company that is known for making quality items and backing them up with excellent customer service.

Material

Consider compatibility, durability, and how your your bike will be ridden.

The Bottom Line

The wide variety of bottom bracket assemblies on the market today evolved out of a demand for bicycle frames that are lighter, stiffer, and cost less to manufacture.

With today’s emphasis on cutting edge technology and innovation, new standards are the norm rather than the exception.

Our decision to manufacture a given standard will be based on its anticipated applications and longevity in the market.

1) Allows more room for the down tube and seat stay tubes

2) Has threads that some find preferable to a pressed system

3) Allows for larger diameter bearings in both internal and external applications; a requirement for 24 and 30 mm crank spindles

Inside are two bearing cups that screw into the frame

1) Right side cup:

2) Left side cup:

ID: 46 mm

OD: 47 mm

Pitch: 1 mm

Length: 12 mm

Threads:

47.75 mm at center relief

Compatible with the largest range of cranks.

Inside are two bearing cups that screw into the frame

1) Right side cup:

2) Left side cup:

ID: 1.340”

OD: 1.370"

Length: 0.50”

Thread:

1.390" at center relief

1) Lighter than traditional threaded cups since no metal sleeve is required in the bottom bracket shell

2) Allows for wider shells and correspondingly bigger frame tubes

3) Improved stiffness without an adverse effect on pedal-stance width

4) Accommodates a wide variety of bottom brackets assemblies, including eccentrics